There is an all too common situation where a shock absorbing fall protection lanyard does not meet fall protection requirements.

Miller Fall Protection puts it like this, “when using a shock absorbing lanyard, it is important to understand how to calculate potential fall distance to avoid contact with a lower level“. A lower level can be the decking of a lower floor, an obstruction below you or even the ground.

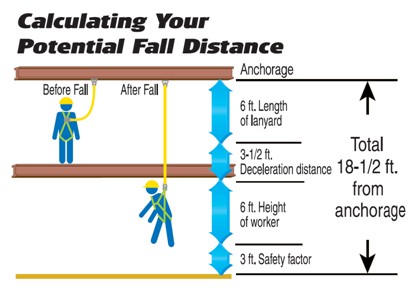

Whenever the distance from your anchor point to that lower level is less than 18.5 feet a shock absorbing fall protection lanyard cannot be used. Take a look at Miller’s diagram below to see why.

Miller explains the above diagram as follows:

- When using a six foot shock absorbing lanyard and a full-body harness, first add the length of the shock-absorbing lanyard [6 ft.] to the maximum elongation of the shock absorber during deceleration [3-1/2 ft.] to the average height of a worker [6 ft.].

- Then, add a safety factor of 3 ft. to allow for the possibility of an improperly fit harness, a taller than average worker and/or a miscalculation of distance.

- The total, 18-1/2 ft., is the suggested safe fall clearance distance, the height at which you must attach to an anchorage to minimize the risk of contact with a lower level.

This means that if a shock absorbing lanyard is used below 18.5 feet, the “lower level” will be struck in the event of a fall. This problem is easily solved.

Shock Absorbing Lanyard Alternatives

A shorter shock absorbing lanyard will provide a few more feet of leeway (like the below 3′ lanyard). However, it also greatly limits the room a worker has to operate. In most cases, a shorter lanyard will not be possible.

The best way to solve this problem is to use a self retracting lifeline. Most self retracting lifelines decelerate much sooner than a shock absorbing lanyard’s 3.5′ deceleration. This reduces potential fall distance.

Unlike a shock absorbing lanyard, a self retracting lifeline contains no slack. Depending on where the SRL is mounted, this factor can also reduce potential fall distance.

Please note, however, that the potential fall distance will still need to be calculated when using a self retracting lifeline.

Downloads:

All the pics are linked to products at Major Safety. There you can get additional info, purchase, or contact us with more questions. We are happy to help.

by Corby Amos